Mastering Sawmill Band Saw Blade Sharpening: Tips for Optimal Performance and Longevity

In the world of woodworking, precision and efficiency are paramount, and the key to achieving both lies in the sharpness of your sawmill band saw blades. Mastering sawmill band saw blade sharpening not only enhances cutting performance but also extends the lifespan of your blades, saving you time and money in the long run. Whether you’re a seasoned sawyer or just starting out, knowing the ins and outs of blade sharpening can transform the way you approach your projects. From understanding the right tools and techniques to recognizing when it’s time for a tune-up, this guide will provide you with invaluable tips to help you achieve optimal performance. Explore the art and science of blade sharpening, and discover how the right practices can turn your saw into a reliable workhorse, ready to tackle any task with unparalleled efficiency. Unlock the full potential of your sawmill and elevate your woodworking game!

Importance of Proper Blade Sharpening

In the realm of woodworking, the sharpness of your sawmill band saw blade is a critical factor that directly influences the quality of your cuts and the efficiency of your work. A properly sharpened blade ensures clean, precise cuts, reducing the risk of damaging the wood or creating uneven surfaces. This precision is particularly important for projects that require tight tolerances and smooth finishes, where even the slightest deviation can compromise the final product. By maintaining a sharp blade, you can achieve consistent results and elevate the overall quality of your woodworking projects.

Moreover, a sharp blade enhances the efficiency of your sawmill operations. When the blade is dull, it requires more force and time to cut through the wood, leading to increased wear and tear on both the blade and the sawmill. This added strain can cause the sawmill to overheat and reduce its lifespan. Conversely, a sharp blade glides through the material with minimal resistance, allowing for faster and more efficient cutting. This not only saves time but also conserves energy and reduces operational costs.

In addition to improving performance and efficiency, regular blade sharpening also extends the lifespan of your sawmill band saw blades. Dull blades are more prone to chipping and breaking, which can result in costly replacements and downtime. By keeping your blades sharp, you minimize the risk of damage and ensure that they remain in optimal condition for longer periods. This proactive approach to maintenance can lead to significant cost savings over time, as you’ll spend less on replacements and repairs. Ultimately, mastering blade sharpening is an investment in the longevity and productivity of your woodworking endeavors.

Types of Band Saw Blades and Their Uses

Understanding the different types of band saw blades and their specific applications is crucial for achieving optimal performance in your woodworking projects. Band saw blades come in various designs, each tailored to handle specific tasks and materials. One of the most common types is the regular tooth blade, characterized by evenly spaced teeth that are ideal for general-purpose cutting. This blade is versatile and can be used for a wide range of materials, including wood, plastic, and metal. Its consistent tooth pattern provides smooth cuts and is suitable for both straight and curved cuts.

Another popular type is the skip tooth blade, which features widely spaced teeth with large gullets. This design allows for efficient chip clearance and reduces the risk of clogging, making it ideal for cutting softwoods and non-ferrous metals. The skip tooth blade is particularly effective for resawing and cutting thicker materials, as the larger gullets help remove debris and prevent overheating. This blade is also well-suited for cutting green or wet wood, as it minimizes the buildup of sawdust and sap.

For more specialized applications, the hook tooth blade is an excellent choice. This blade has a positive rake angle and aggressive tooth geometry, making it perfect for cutting hard and dense materials. The hook tooth blade excels in applications that require fast and aggressive cutting, such as ripping hardwoods and cutting through dense plastic or metal. Its design ensures efficient material removal and reduces the risk of blade binding or stalling. Understanding the strengths and limitations of each blade type allows you to select the right blade for your specific needs, ensuring optimal performance and longevity.

Maintenance of Blades for Blade Sharpening

It is important to have a set of basic maintenance tools on hand. These include a wire brush for cleaning the blade, a set of pliers for adjusting the tension, and a lubricant to reduce friction and prevent rust. Regular maintenance is essential for keeping your blades in top condition and ensuring optimal performance. By investing in quality sharpening tools and equipment, you can achieve professional-grade results and extend the lifespan of your sawmill band saw blades.

Common Mistakes to Avoid When Taking a Blade for Sharpening

A common mistake is neglecting to clean the blade before taking it to be sharpened. Buildup of resin, pitch, and debris can interfere with the sharpening process, causing the sharpening tool to skip or slip. This can result in an uneven cutting edge and reduce the overall sharpness of the blade. Always take the time to thoroughly clean the blade before sharpening, ensuring that all teeth are free of buildup. This will not only improve the sharpening results but also extend the life of your blades.

Maintenance Tips for Prolonging Blade Life

Proper maintenance is essential for prolonging the life of your sawmill band saw blades and ensuring consistent performance. One of the most important maintenance tasks is regular cleaning. After each use, clean the blade thoroughly to remove any debris, resin, or pitch that may have accumulated. Use a wire brush or a specialized cleaning solution to scrub the blade, paying particular attention to the teeth. Regular cleaning prevents buildup that can interfere with cutting performance and cause premature wear.

Another key maintenance task is checking and adjusting the tension of the blade. Proper tension is crucial for achieving clean, precise cuts and preventing blade damage. Use a tension gauge to measure the tension and adjust it according to the manufacturer’s specifications. If the blade is too loose, it may wobble or drift during cutting, leading to inaccurate cuts and increased wear. If the blade is too tight, it may break or cause excessive strain on the sawmill. Regularly checking and adjusting the tension ensures optimal cutting performance and extends the life of the blade.

In addition to cleaning and tensioning, it is important to inspect the blade for signs of wear and damage. Look for cracks, missing teeth, or other defects that may compromise the performance of the blade. If any issues are found, address them promptly to prevent further damage. Regularly lubricating the blade can also help reduce friction and prevent rust, further extending the life of the blade. By following these maintenance tips, you can keep your sawmill band saw blades in top condition and ensure long-lasting performance.

Signs Your Band Saw Blade Needs Sharpening

Recognizing the signs that your band saw blade needs sharpening is crucial for maintaining optimal cutting performance. One of the most obvious signs is a noticeable decrease in cutting efficiency. If you find that you need to exert more force to push the material through the blade, or if the blade is struggling to make clean cuts, it is likely that the blade is dull and needs sharpening. A sharp blade should glide through the material effortlessly, producing smooth and precise cuts.

Another sign that your blade needs sharpening is the presence of burn marks on the wood. When a blade is dull, it generates more friction and heat during cutting, which can scorch the wood and leave unsightly burn marks. If you notice burn marks on your workpieces, it is a clear indication that the blade is not cutting efficiently and needs to be sharpened. Additionally, a dull blade may produce rough or jagged edges on the cuts, rather than the clean, smooth edges that a sharp blade provides.

Increased noise and vibration during cutting can also be a sign that your blade needs sharpening. A dull blade tends to vibrate more and produce a louder, harsher sound as it struggles to cut through the material. This not only affects the quality of the cut but also puts additional strain on the sawmill and the blade itself. If you notice any of these signs, it is important to sharpen your blade promptly to restore its cutting performance and prevent further damage.

Professional Sharpening Services vs. DIY

When it comes to sharpening band saw blades, you have the option of doing it yourself or seeking professional sharpening services. Each approach has its advantages and considerations. DIY sharpening allows you to maintain control over the process and can be more cost-effective in the long run. DIY sharpening also allows for greater flexibility, as you can sharpen your blades whenever needed without having to wait for a service provider.

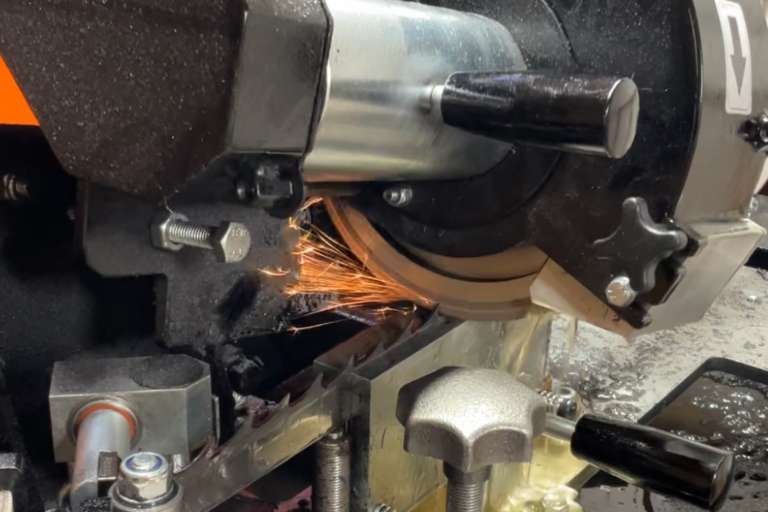

However, DIY sharpening requires a certain level of skill and knowledge. It is important to understand the proper techniques and use the right tools to achieve consistent and effective results. Mistakes in sharpening can lead to uneven teeth, altered tooth geometry, or even damage to the blade. If you are new to sharpening or unsure of your abilities, seeking professional sharpening services may be a better option. Professional sharpeners have the expertise and specialized equipment to ensure precise and consistent sharpening, restoring your blades to their optimal condition.

Professional sharpening services can also save you time and effort, allowing you to focus on your woodworking projects. While there is a cost associated with professional sharpening, it can be a worthwhile investment, especially for those who use their sawmill frequently or for demanding applications. Ultimately, the choice between DIY sharpening and professional services depends on your level of experience, the frequency of use, and your specific needs. Both approaches can help you achieve optimal performance and longevity for your band saw blades.

Conclusion and Final Thoughts on Blade Care

Mastering sawmill band saw blade sharpening is a valuable skill that can significantly enhance the performance and longevity of your blades. By understanding the importance of proper sharpening, selecting the right tools and techniques, and avoiding common mistakes, you can achieve professional-grade results and ensure consistent cutting performance. Regular maintenance, including cleaning, tensioning, and inspecting the blade, is essential for keeping your blades in top condition and preventing premature wear.

Recognizing the signs that your blade needs sharpening and taking prompt action can prevent further damage and ensure optimal cutting efficiency. The key is to prioritize blade care and make it a regular part of your woodworking routine. Investing time and effort in blade sharpening and maintenance can lead to significant cost savings and improved productivity in the long run.

In conclusion, mastering sawmill band saw blade sharpening is more than just a technical skill; it is an art that requires attention to detail, practice, and a commitment to excellence. By following the tips and guidelines outlined in this guide, you can unlock the full potential of your sawmill and elevate your woodworking game. With sharp, well-maintained blades, you can tackle any project with confidence and precision, achieving results that reflect your dedication and craftsmanship.

📦 Ready to Ship Your Bandsaw sawmill Blades?

Now that you know how to maintain your blade, you’re ready to send it in for sharpening. At Cutting Edge Sawmill, we sharpen and set bandsaw blades for sawyers all across the U.S. We’ll get your blades back to you fast and cutting clean.

📞 Call us at 417-342-0127

🌐 CuttingEdgeSawmill.com